how to program hmi module

Programming an HMI (Human-Machine Interface) module typically involves using specialized software and hardware specific to the manufacturer and model of the HMI module. These modules are commonly used to control and monitor industrial processes and equipment. The programming process may vary significantly depending on the manufacturer and the HMI software used. Here are some general steps that can help guide you through the programming process:

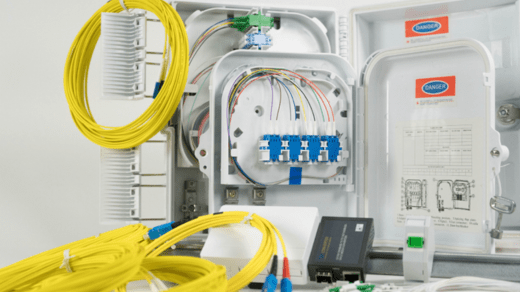

1. Gather Necessary Equipment:

- Ensure you have the necessary equipment, including the HMI module, a computer with the programming software installed, and any required communication cables.

2. Install Programming Software:

- Install the manufacturer’s programming software on your computer. This software is specific to the HMI module you are working with and is essential for programming and configuring the module.

3. Connect HMI Module:

- Connect the HMI module to your computer using the appropriate communication cable. The type of cable and connection method will depend on the specific HMI module and manufacturer.

4. Power Up the HMI Module:

- Ensure the HMI module is powered up and properly connected to the industrial equipment it will control or monitor. This may involve connecting power cables, inputoutput devices, and sensors.

5. Launch the Programming Software:

- Start the programming software on your computer.

6. Establish Communication:

- Use the software to establish communication between your computer and the HMI module. This typically involves configuring communication settings, such as selecting the correct communication port and baud rate.

7. Create or Load a Project:

- Depending on your requirements, you can either create a new project from scratch or load an existing project if available.

8. Design the HMI Interface:

- Use the software’s graphical interface to design the HMI screens and user interface elements. This may include creating buttons, displays, alarms, and data entry fields.

9. Program Functionality:

- Write the necessary logic and functionality to control and monitor the industrial processes and equipment. This often involves using a programming language or a graphical programming environment provided by the software.

10. Test the HMI Module: – After programming, test the HMI module’s functionality and user interface to ensure it operates as intended. Verify that it communicates with the industrial equipment and displays relevant data accurately.

11. Debug and Optimize: – Debug any issues or errors that arise during testing and optimize the program for efficiency and reliability.

12. Save and Deploy: – Once the programming and testing are successful, save the project and deploy it to the HMI module. This may involve downloading the program to the module’s memory.

13. Monitor and Maintain: – Regularly monitor the HMI module’s performance and make any necessary adjustments or updates to the program as industrial processes and equipment change.

Please note that these are general guidelines, and the specific steps and procedures can vary widely depending on the manufacturer, model, and software used for the HMI module. Always refer to the manufacturer’s documentation and user manuals for detailed instructions and guidance specific to your HMI module. Additionally, programming industrial equipment often requires specialized knowledge and training, so it’s essential to have expertise in the field or work with professionals experienced in industrial automation.