The Ultimate Guide to T Patti Profiles and T Profiles

When it comes to the construction and design industries, the significance of T Patti profiles and T profiles cannot be overstated. These essential components play a crucial role in various applications, offering both structural support and aesthetic appeal. But what exactly are T Patti profiles and T profiles, and why are they so important? Let’s delve into this comprehensive guide to uncover everything you need to know about these versatile profiles.

Understanding T Patti Profiles

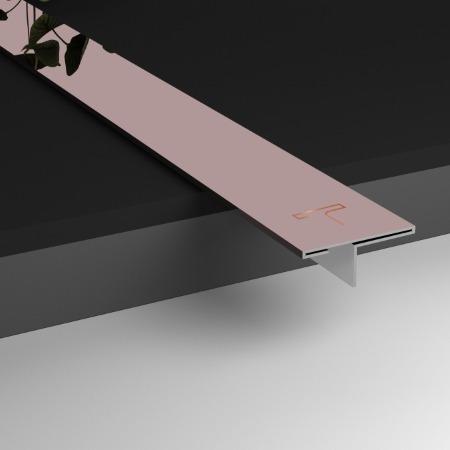

Definition and Basic Structure

T Patti profiles, often referred to simply as T profiles, are long, slender structural elements with a T-shaped cross-section. This unique shape provides them with excellent strength and stability, making them ideal for a wide range of applications. The vertical part of the ‘T’ is known as the web, while the horizontal part is called the flange.

Common Materials Used

T Patti profiles can be made from various materials, each offering distinct advantages. The most common materials include stainless steel, mild steel, aluminum, and brass. Among these, stainless steel is particularly favored for its strength, durability, and resistance to corrosion.

Types of T Patti Profiles

Stainless Steel T Patti

Stainless steel T Patti profiles are widely used due to their superior corrosion resistance and strength. They are ideal for environments where durability and hygiene are paramount, such as in kitchens, laboratories, and hospitals.

SS T Patti

SS t patti refers specifically to T Patti profiles made from stainless steel. These profiles are available in various grades, such as 304 and 316, each offering different levels of corrosion resistance and mechanical properties.

T Patti Sizes and Dimensions

Standard Sizes

T Patti profiles come in a range of standard sizes to cater to different needs. Common dimensions include widths ranging from 10mm to 50mm and thicknesses from 1mm to 5mm. These sizes are suitable for most general applications.

Custom Sizes

For specialized applications, custom sizes can be manufactured to meet specific requirements. This flexibility ensures that T Patti profiles can be used in a wide variety of projects, from intricate design elements to heavy-duty structural components.

Applications of T Patti Profiles

Construction Industry

In the construction industry, T Patti profiles are used for framing, structural support, and as reinforcement elements. Their strength and stability make them ideal for creating robust frameworks in buildings and infrastructure projects.

Interior Design

T Patti profiles add a touch of elegance to interior spaces. They are commonly used in decorative elements, partition walls, and as edging for countertops and panels. Their sleek appearance and versatility make them a favorite among interior designers.

Automotive Industry

The automotive industry utilizes T Patti profiles in the manufacturing of various vehicle components. Their strength-to-weight ratio is beneficial for creating lightweight yet durable parts, contributing to overall vehicle efficiency and performance.

Benefits of Using T Patti Profiles

Durability

One of the primary benefits of T Patti profiles is their durability. Materials like stainless steel provide long-lasting performance, even in harsh environments. This ensures that structures and components remain safe and reliable over time.

Aesthetic Appeal

T Patti profiles offer a clean, modern look that enhances the aesthetic appeal of any project. Whether used in visible architectural elements or hidden structural supports, they contribute to a polished and professional finish.

Versatility

The versatility of T Patti profiles is another significant advantage. They can be used in a wide range of applications, from heavy-duty construction to delicate interior design. This flexibility makes them a valuable addition to any project.

Manufacturing Process

Raw Material Selection

The manufacturing process begins with the careful selection of raw materials. High-quality materials ensure that the final product meets the required standards for strength and durability.

Fabrication Techniques

Various fabrication techniques are used to create T Patti profiles, including extrusion, rolling, and welding. Each method has its advantages and is chosen based on the specific requirements of the profile being produced.

Stainless Steel T Profiles

Characteristics of Stainless Steel

Stainless steel is renowned for its excellent mechanical properties, including high tensile strength, resistance to impact, and superior corrosion resistance. These characteristics make it an ideal material for T profiles used in demanding environments.

Popular Grades

The most popular grades of stainless steel for T profiles are 304 and 316. Grade 304 is known for its general corrosion resistance and ease of fabrication, while grade 316 offers enhanced resistance to corrosion, especially in marine and industrial environments.

SS T Profiles in Different Industries

Industrial Applications

In industrial settings, SS T profiles are used in machinery, equipment, and structural frameworks. Their robustness and resistance to wear make them suitable for heavy-duty applications.

Commercial Uses

Commercial applications of SS T profiles include retail fixtures, signage, and display stands. Their sleek appearance and durability make them an excellent choice for high-traffic areas where both aesthetics and performance are important.

Choosing the Right T Patti Profile

Factors to Consider

When selecting a T Patti profile, several factors need to be considered, including the material, size, and intended application. It’s essential to choose a profile that meets the specific requirements of your project to ensure optimal performance.

Cost vs. Quality

While cost is always a consideration, it’s crucial not to compromise on quality. Investing in high-quality T Patti profiles ensures longevity and reduces maintenance costs over time, making it a cost-effective choice in the long run.

Installation of T Patti Profiles

Tools Required

The installation of T Patti profiles requires basic tools such as a measuring tape, saw, drill, screws, and a level. Having the right tools on hand ensures a smooth and efficient installation process.

Step-by-Step Installation Guide

- Measure and mark the desired length of the T Patti profile.

- Cut the profile to the required size using a saw.

- Position the profile in place and mark the drilling points.

- Drill holes at the marked points.

- Secure the profile using screws, ensuring it is level and aligned.

- Check for any adjustments and make sure the profile is firmly attached.

Maintenance and Care

Cleaning Tips

Regular cleaning is essential to maintain the appearance and performance of T Patti profiles. Use a mild detergent and water solution to clean the surface, avoiding abrasive cleaners that can scratch the material.

Preventing Corrosion

For stainless steel profiles, applying a protective coating can help prevent corrosion. Regular inspections and maintenance are also crucial to ensure the profiles remain in good condition.

Innovations in T Patti Profiles

Recent Developments

Recent developments in T Patti profiles include advancements in materials and fabrication techniques. Innovations such as laser cutting and 3D printing have opened up new possibilities for creating intricate and custom profiles.

Future Trends

The future of T Patti profiles looks promising, with trends focusing on sustainability and enhanced performance. New materials and eco-friendly manufacturing processes are being explored to meet the growing demand for environmentally responsible products.

Comparing T Patti Profiles with Other Profiles

Advantages Over Other Profiles

T Patti profiles offer several advantages over other types of profiles, including superior strength, durability, and aesthetic appeal. Their unique T-shaped design provides additional stability and support compared to flat or L-shaped profiles.

Cost Comparison

While T Patti profiles may be more expensive upfront, their long-term benefits, such as reduced maintenance and increased longevity, make them a cost-effective choice in the long run.

Conclusion

In conclusion, T Patti profiles and T profiles are indispensable components in various industries, offering a perfect blend of strength, durability, and aesthetic appeal. By understanding the different types, applications, and benefits of these profiles, you can make informed decisions for your projects, ensuring optimal performance and longevity.