Choosing the Right Fiber Optic Gear Products for Your Project

Fiber optic technology has become a crucial part of modern communication, networking, and data transfer. Whether you are setting up a small business network, working on a large-scale industrial project, or upgrading an existing system, choosing the right fiber optic gear is essential.

With so many products available, making the right choice can feel overwhelming. Factors like speed, distance, durability, and compatibility play a big role in selecting the right fiber optic gear. Understanding these factors helps you make an informed decision and avoid costly mistakes.

Understand Your Project Requirements

Before buying fiber optic gear, take time to understand your project needs. Consider the distance the data needs to travel and the speed you require. Short-distance connections, like within an office or a data center, may need multimode fiber, while long-distance connections often require single-mode fiber.

Bandwidth requirements also matter. If your project involves high-speed data transfer, such as in telecommunication networks or video streaming services, you will need gear that supports higher bandwidth.

Choose the Right Fiber Optic Cables

The type of fiber optic cable you choose impacts performance. Single-mode fiber cables work best for long-distance communication, such as connecting cities or large campuses. These cables use a narrow core that allows data to travel further without much signal loss.

On the other hand, multimode fiber cables work well for shorter distances, like inside buildings or small networks. They have a wider core and support multiple data streams at the same time. Selecting the right cable ensures durability and efficiency in your project.

Pick Compatible Connectors and Transceivers

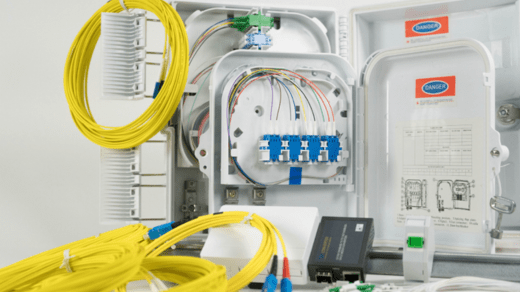

Connectors and transceivers play a key role in fiber optic communication. Using the wrong connectors can lead to poor performance or even system failure. Common types include LC, SC, and ST connectors, each suited for different applications.

Make sure the connectors match your existing hardware to avoid compatibility issues. Transceivers convert electrical signals into optical signals and vice versa. They come in various types, such as SFP, SFP+, and QSFP, depending on the required data transmission speed.

Consider Network Switches and Patch Panels

Network switches and patch panels manage and distribute fiber optic connections efficiently. A well-organized system improves maintenance and reduces downtime. When choosing a network switch, ensure it has enough ports and supports the necessary speed for your project.

Patch panels keep fiber optic connections structured and reduce cable clutter. They allow easy access for future upgrades and troubleshooting. Investing in a good-quality patch panel helps maintain an organized and efficient network setup.

Ensure Quality and Reliability

Not all Fiber Optic Gear Products is the same. Low-quality products can cause performance issues, frequent breakdowns, and increased maintenance costs. Always choose products from reputable manufacturers that meet industry standards.

Reliable gear lasts longer and provides stable performance, reducing the need for replacements or repairs. Testing the equipment before full installation helps detect any issues early. Using certified cables, connectors, and transceivers ensures a smooth and efficient network.

Conclusion

Selecting the right fiber optic gear for your project requires careful planning. Understanding your project’s requirements, choosing the right cables, using compatible connectors and transceivers, and investing in quality equipment all contribute to a reliable system.

Taking the time to make informed decisions helps avoid costly mistakes and ensures long-term success. Whether working on a small office setup or a large-scale network, the right fiber optic gear makes a big difference in performance and efficiency.